Pin Pricked Hose Assemblies

Pin-pricking a hose cover permits steam, air and other gaseous products to escape through the hose’s outer membrane. This reduces the risk of such gases building up within the hose outer cover and prevents the hose from becoming blistered or bubbled, improving the reliability and life-time of the hose. Without the pin-pricks, bubbles or blisters could start to appear in the cover

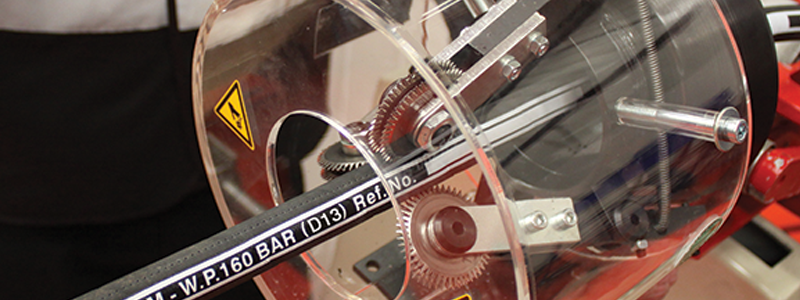

of the hose, damaging its reliability. Therefore pin-pricking can improve the reliability and life-time of the hose. This process is performed by a wheel that passes along the hose when it is pulled from the mandrel, pricking the cover in a series of uniform punctures that stop at the layer of reinforcement.

With our hose pricking equipment we can guarantee our tooling will perforate the hose to the correct tolerance, for hoses ranging from 11.5mm to 85mm Ø OD.

We can offer pin-pricked hose in the following formats:

- Full coils

- Bespoke cut lengths

- Fully assembled

All of our pin-pricked hoses will arrive specifically labelled to ensure easy identification and differentiation to standard hose.