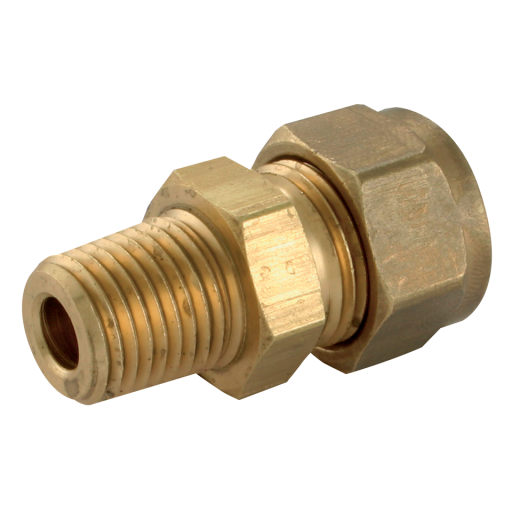

Male Studs, Wade - NPT & API Male x Tube

Viewing 13 of 13

Wade couplings consistently produce cost effective, reliable, leak-tight joints.

They can be found in general use throughout the following industries: hydraulic, pneumatic, automotive, locomotive, LPG, oil and gas, power generation, air conditioning, heating and ventilation, and also for applications where there is a need for the added safety provided by an engineering fitting.

All Wade compression fittings are manufactured to... Read more.

Product Information

Product CodeWADE-4061/3APIDescriptionList Price (£)12.28Qty |

|

Product CodeWADE-4063/1APIDescriptionList Price (£)2.20Qty |

|

Product CodeWADE-1063/APIDescriptionList Price (£)5.86Qty |

|

Product CodeWADE-4063/8APIDescriptionList Price (£)16.55Qty |

|

Product CodeWADE-4063/11APIDescriptionList Price (£)13.22Qty |

|

Product CodeWADE-1065/APIDescriptionList Price (£)4.59Qty |

|

Product CodeWADE-4068/1APIDescriptionList Price (£)12.90Qty |

|

Product CodeWADE-4068/3-APIDescriptionList Price (£)9.76Qty |

|

Product CodeWADE-1068/APIDescriptionList Price (£)4.83Qty |

|

Product CodeWADE-4068/11APIDescriptionList Price (£)13.52Qty |

|

Product CodeWADE-4071/3APIDescriptionList Price (£)21.60Qty |

|

Product CodeWADE-4071-8APIDescriptionList Price (£)6.94Qty |

|

Product CodeWADE-1071-APIDescriptionList Price (£)5.94Qty |