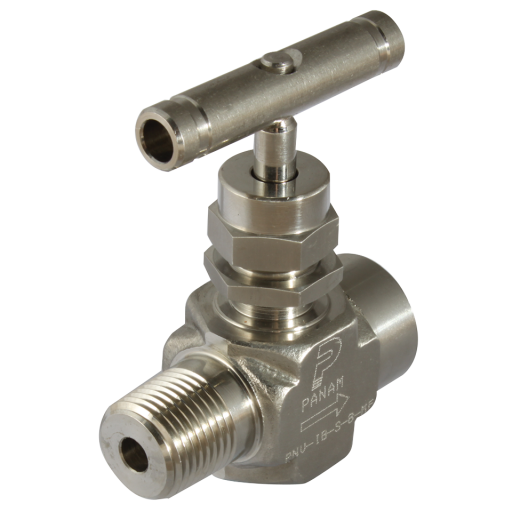

10,000 psi Rated Imperial Needle Valves, Panam - Male x Female, NPTF

Viewing 6 of 6

The 'HP' series of needle valves are specially designed & manufactured for us in corrosive & hazardous environments.

These valves are for use in process control, instrumentation & flow control applications.

Feature Benefits:

One piece body construction for strength & safety.

Non rotating Vee tip design, which forms a bearing joint with the stem eliminating any rotation between the plug... Read more.

Product Information

Product CodePNV-HP-S-2-MFDescriptionList Price (£)89.26Qty |

|

Product CodePNV-HP-S-4-MFDescriptionList Price (£)104.48Qty |

|

Product CodePNV-HP-S-6-MFDescriptionList Price (£)107.20Qty |

|

Product CodePNV-HP-S-8-MFDescriptionList Price (£)171.96Qty |

|

Product CodePNV-HP-S-12-MFDescriptionList Price (£)94.98Qty |

|

Product CodePNV-HP-S-16-MFDescriptionList Price (£)384.44Qty |