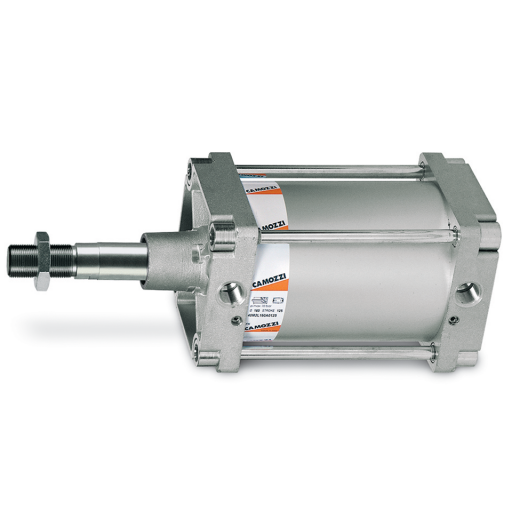

Series 40 Double Acting ISO15552 Cylinders, Camozzi - 3/4" Magnetic, ø200mm

Viewing 18 of 18

Series 40 cylinders have been designed in compliance with ISO 15552 standards and with previous DIN/ISO 6431-VDMA 24562 standards.

A permanent magnet on the piston of these cylinders is able to send, through proximity switches mounted on the cylinder sliding axis, electrical signals to indicate its position.

Type of construction: with tie-rods.

Operation: double-acting.

Materials: aluminium end blocks and piston,... Read more.

Product Information

Product Code40M2L200A0050DescriptionList Price (£)915.47Qty |

|

Product Code40M2L200A0080DescriptionList Price (£)899.30Qty |

|

Product Code40M2L200A0100DescriptionList Price (£)963.49Qty |

|

Product Code40M2L200A0150DescriptionList Price (£)1,010.76Qty |

|

Product Code40M2L200A0200DescriptionList Price (£)1,058.06Qty |

|

Product Code40M2L200A0250DescriptionList Price (£)1,196.13Qty |

|

Product Code40M2L200A0300DescriptionList Price (£)1,261.20Qty |

|

Product Code40M2L200A0400DescriptionList Price (£)1,364.41Qty |

|

Product Code40M2L200A0500DescriptionList Price (£)1,466.49Qty |

|

Product Code40M2L200A0600DescriptionList Price (£)1,570.44Qty |

|

Product Code40M2L200A0700DescriptionList Price (£)1,404.39Qty |

|

Product Code40M2L200A0800DescriptionList Price (£)1,771.32Qty |

|

Product Code40M2L200A0900DescriptionList Price (£)1,584.41Qty |

|

Product Code40M2L200A1000DescriptionList Price (£)1,711.30Qty |

|

Product Code40M2L200A1250DescriptionList Price (£)1,936.33Qty |

|

Product Code40M2L200A1500DescriptionList Price (£)2,161.35Qty |

|

Product Code40M2L200A1750DescriptionList Price (£)2,386.39Qty |

|

Product Code40M2L200A2000DescriptionList Price (£)2,611.41Qty |